Jiangsu Huaqi Electric Co., Ltd. (formerly Jiangsu Ramsey Electric Technology Co., Ltd.) provides a complete set of electronic measurement system solutions. Huaqi Electric has many years of experience in the design manufacture of quantitative feeders, advanced technology strong structure Ensure the reliable stability unmatched versatility of Jiangsu Huaqi quantitative feeder.

System Overview

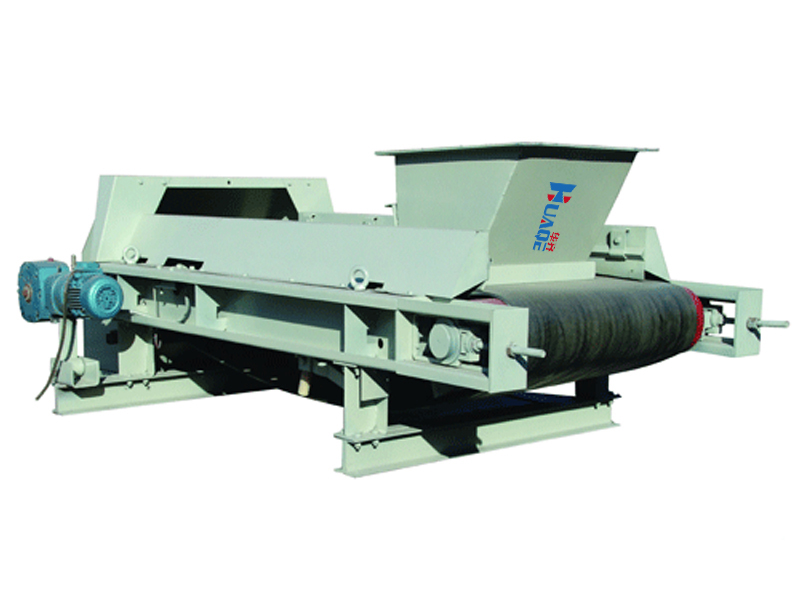

The DEL/DEM type quantitative feeder is a new generation product produced by our company by introducing Thermo Ramsey technology. It has the characteristics of high measurement control accuracy stable performance. The unique optimized design makes it suitable for use under harsh working conditions, adopts the corresponding structure hopper type according to the specific situation, which has economically solved many problems in feeding. It is widely used in the quantitative transportation of granular materials in industries such as building materials, metallurgy, iron steel, steel, chemical, coal, ceramics.

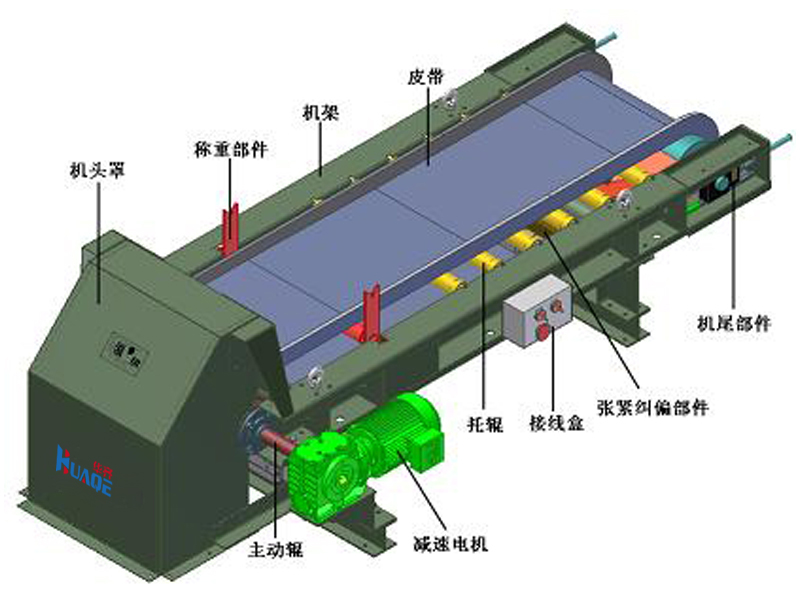

Body composition

DEM/DEL frequency conversion speed regulation quantitative feeder is mainly composed of belt feeder weighing device.

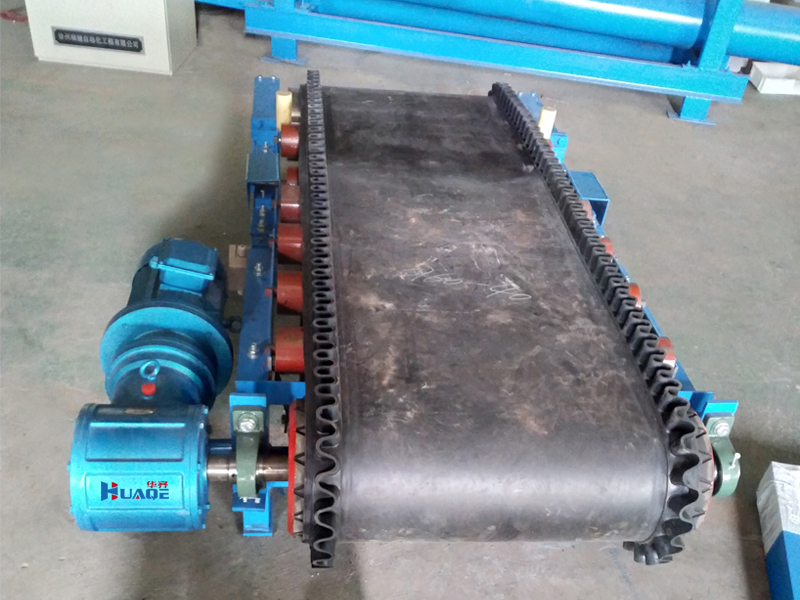

(1) Variable frequency speed regulation quantitative feeder: conveyor bracket, non-interface annular skirt belt, frequency conversion speed regulation motor, frequency converter, etc.

(2) Electronic weighing device: including industrial microcomputer, speed sensor high precision sensor.

System Features

●Using the high-performance electronic belt scale produced by our company, it can ensure the accuracy of measurement long-term stability

●Frequency conversion speed regulation, stable operation, energy saving consumption reduction, can also meet the requirements of on-site open-loop closed-loop flow adjustment

●Perfect alarm system enables you to find eliminate faults such as blocking, breaking, overloading belt deviation in time

●Using high temperature resistant belt, long service life in harsh environment

●High-resolution weighing sensor with minimum displacement of 0.1 mm ensures accurate measurement value.

●High resolution digital pulse speed sensor to ensure accurate speed value.

●Gravity automatic tensioning device to ensure constant belt tension, avoid belt slippage excessive tension.

●Automatic belt rectification device to avoid affecting production due to belt deviation.

●Pear-shaped scraper clears the debris on the lower belt to the side. Avoid the debris between the belt the roller surface to damage the belt.

●The scraper inside outside of the belt avoids the change of belt sticky material tare weight.

●Without assistance, belt replacement is convenient, simplifying maintenance.

●Automatic self-aligning bearings are adopted for the master slave drums, which is very convenient for installation adjustment.

●The actual feeding accuracy of various bulk materials is better than the set feed rate of ±0.5%.

●The feeding rate is about 50kg/h-2000t/h.

●Conveying bandwidth 500mm-1800mm.

●The center distance of the roller is 1000mm-8000mm, using the plug-in system, the size can be customized according to user requirements.

●Output interface: a variety of options, can be connected with DCS system.

●Ambient temperature: scale body -10℃~+60℃ instrument -10℃~+45℃

●The weighing frame adopts high-strength rectangular tube, with high rigidity good stability.

● Shaft-mounted geared motor with low vibration high stability.

● Automatic belt tensioning device ensures constant belt tension measurement accuracy.

● The conveying automatic deviation-correcting device avoids the influence of production due to belt deviation.

● Special structure weighing roller, high-precision bearing, small radial runout, flexible rotation high stability.

● Lightweight tape polyester tape, good flexion performance, light weight tare.

● The speed measuring device is on the driven roller, the speed tracking is accurate.

●Small flow can be driven by stepper motor, with accurate tracking speed small jitter.

Technical Parameters

Measurement error: ±0.5~1.0%

Belt width: 300~1200mm

Belt speed: 0.01~0.2m/s

Drum center distance: ≥1.0m

Output interface: multiple options, can be connected with DCS system.

Ambient temperature:

Scale body -10℃~+60℃

Instrument -10℃~+45℃

Working power supply:

Meter AC220V±15% 50Hz±2%

Scale body AC220V±15% 50Hz±2%