ICS-17B series electronic belt scale

Jiangsu Huaqi Electric Co., Ltd. (formerly Jiangsu Ramsey Electric Technology Co., Ltd.) fully absorbed applied the weighing process of the world famous brand Thermo Ramsey, developed produced various types of electronic belt scales with precision, developed belt scale application software for users. In order to make the weighing data more effective, reduce production costs reduce costs.

Product Details

ICS17B series belt scales, the dynamic cumulative error is less than ±0.5%, used in factory process weighing, the main belt conveyor the coal feeder feeder with a long center distance between the inlet outlet, measure the production volume, control product loading monitor product inventory to provide important information for modern enterprise management.

ICS17B series belt scale is mainly composed of four parts: ICS17B fully suspended weighing bridge supported by two trunnions, two weighing sensors, digital speed sensors, 2000 series totalizer.

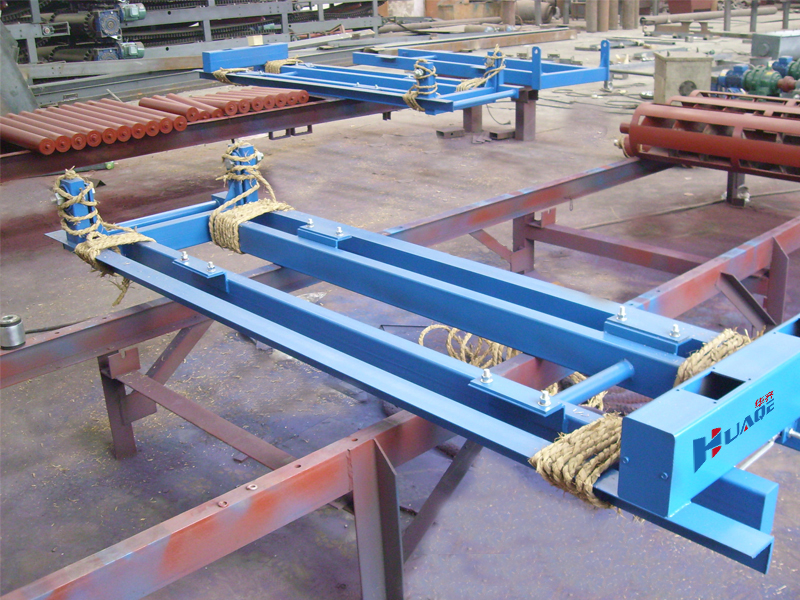

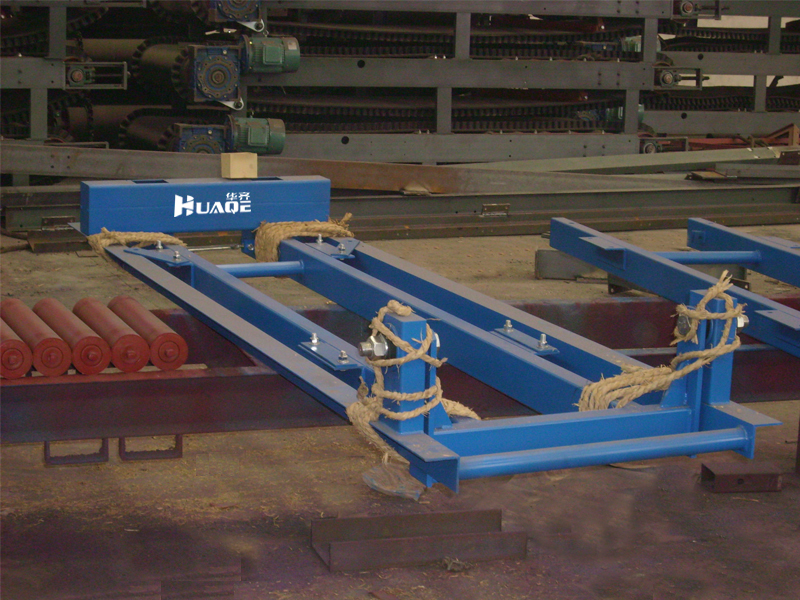

ICS17B weighing bridge

The ICS17B weighing bridge is equipped with two sets of weighing rollers on the lever, supported by dual load cells, the outer support adopts frictionless trunnion fulcrums. This closed device can prevent shock, moisture, corrosion prevent material accumulation, so it is The problems caused by the use of knife edge devices bearing devices do occur in the environment.

The main beam of the weighing bridge is made of rectangular steel pipes, which makes the whole weighing bridge have high enough rigidity, small self-weight, the smallest ash accumulation area. The weighing bridge can be directly installed in belt conveyor racks of various widths, located between the upper lower belts, does take up space. It is a unit that has been assembled in the factory can be quickly easily installed calibrated.

Technical Parameters

▪ Measuring accuracy: ±0.5% ▪ Weighing range: 0~6000t/h ▪ Belt width: 500~2200mm

▪ Belt speed: 0.01~4.0m/s ▪ Belt conveyor inclination angle: 0°~18° ▪ Remote transmission: 1200m

Working installation environment

▪ Ambient temperature: Mechanical: -20°C~+50°C Instrument: -20°C~+40°C

▪ Power supply voltage: 220VAC (+10%~-15%) 50HZ±2%

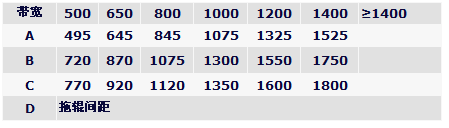

Dimensions

Note: The size of the bandwidth listed in the table is determined according to the actual rack

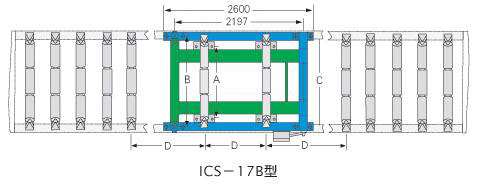

Installation diagram

Note: D in the picture is the distance between the two rollers of the conveyor