One end of the wire rope of the pull switch is fixed on a fixed wire bolt the other end is fixed on the switch arm. The wire rope should be supported by a hole bolt every 3 meters. The distance between the switch the fixed point should exceed 30 meters. Between the two switches The distance does exceed 60 meters. When the external force causes the switch arm to rotate to the alarm position, the micro switch is touched locked until it is manually reset. Suitable for indoor outdoor installation. Special surface treatment can be used in acid, alkali salt areas. Nickel-plated surfaces are used in areas with strong corrosion.

▲Product features:

--The rope pull switch is bi-directionally touched can be installed either in the middle of the conveyor at both ends.

--Universal installation design enables the shape of the cable to be installed either on the top of the longitudinal beam of the conveyor on both sides.

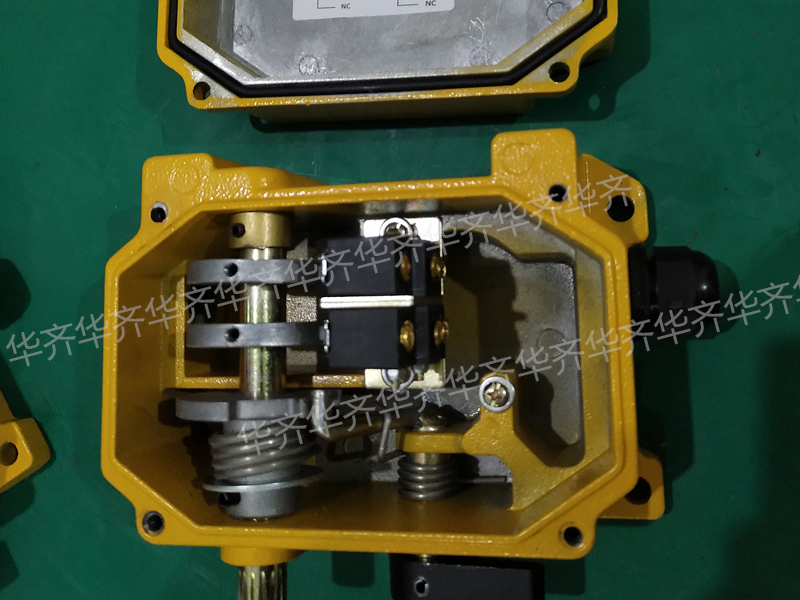

--Rugged cast aluminum housing with NEMA4 protection grade, special surface treatment can be selected for special environment.

--Integrated cover plate makes wiring switch adjustment easy simple without disassembling the switch.

--Compact structural design.

- Eye-catching black arm set against yellow silver shell, easy to distinguish alarm normal state.

--Provide complete accessories, including wire ropes, rope clamps cable support bolts.

- Manual lever reset.

▲Scope of application

Suitable for emergency normal shutdown of the following equipment

*Conventional belt conveyor

*Shuttle conveyor

*Skirt-type feeding conveyor

*Bucket elevator

*Packaging production line

*Stacking/reclaiming system, crane, excavator

*Ship loading unloading system

*Horizontal feeder