Digital electronic truck scale

Truck scales are also known as weighbridges, are the main weighing equipment used in the measurement of bulk goods such as factories, mines businesses. Truck scales that were common before the 1980s are also called mechanical weighbridges. In the mid-1980s, as high-precision load cell technology matured, mechanical weighbridges were gradually replaced by electronic truck scales with high accuracy, good stability, easy operation.

Static weighing, verification accuracy ≤±0.5%. High-end weighing technology plus precision machinery manufacturing process, strong environmental adaptability, anti-corrosion, torsion lateral resistance. Fully automatic precision welding, stronger rigidity, longer lasting use.

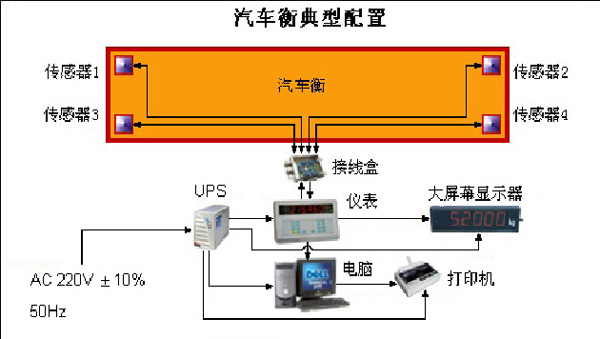

Components accessories of truck scale

The main components of the truck scale are sensors, weighing platform, instrument, junction box, data cable, slope (no base type)

Load-bearing force-transmitting structure: The weight of the object is transferred to the mechanical platform of the load cell. There are two types of steel structure steel-concrete structure.

High-precision weighing sensor: It is the core component of the automobile scale, it plays the role of converting the weight value into the corresponding measurable electrical signal. Its quality is directly related to the quality of the whole weighing instrument.

Weighing display instrument: used to measure the electrical signal transmitted by the sensor, then display the weight reading through special software processing, can further transfer the data to the printer, large screen display, computer management system.

Features

1. With RAMZY-TECH high-end weighing technology, the accuracy is more accurate.

2. Exquisite manufacturing process, fully automatic welding, anti-corrosion, torsion lateral resistance of weighing platform, durable more reliable.

3. With the unattended system, it is more comprehensive to prevent cheating, the data report is easy to print.

4. The professional engineering team tailor-made the system solution, which is more in line with personal needs.

working environment:

Instrument temperature range: -10℃~+45℃

Sensor temperature range: -40℃~+65℃

Relative humidity: ≤ 95%

Working voltage: 220V±10%, frequency 50Hz

Standard sizes

Table size: different models, different sizes

Weight: different models, different weight

Thickness: different models, different thickness

After-sales service

Senior engineers professionally provide you with perfect sales service guidance, pre-sale professional program design, product selection guidance, installation commissioning during sale, three-year follow-up maintenance service after sale.