Jiangsu Huaqi Electric Co., Ltd. (formerly Jiangsu Ramsey Electric Technology Co., Ltd.) provides a complete set of electronic measurement system solutions. Jiangsu Huaqi has many years of experience in the design manufacture of spiral weighing feeders, which are widely used in power, Coal, metallurgy, mining, port, chemical industry, building materials other industries. Advanced technology sturdy structure ensure the reliable stability unmatched versatility of Jiangsu Huaqi Screw Weighing Feeder.

System Overview

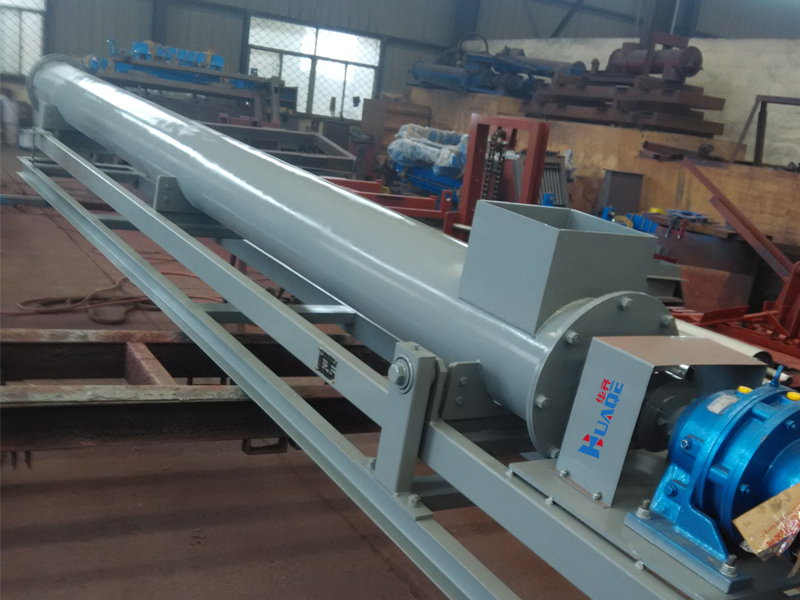

The screw weighing feeder LXC series is a production measurement equipment for continuous transportation, dynamic measurement controlled feeding of various powdery granular materials. The powder material is fed conveyed, the weighing quantitative feeding control are It is integrated as an automatic device for metering ingredients, which can provide accurate metering data control means for on-site management operation. Widely used in industries such as cement, chemical industry, metallurgy, ceramics, grain, building materials, etc.

Equipment composition

The spiral weighing system is mainly composed of a steady-flow feeding screw, a weighing bridge, a reduction motor, a weighing sensor, a speed sensor, a weighing control instrument an electronic control system. The weighing bridge is a lever type, the lever pivot point uses a trunnion Support, affected by corrosion external factors on the measurement accuracy; the speed sensor is placed on the non-driving end of the spiral body, the measurement is accurate.

working principle

The screw weighing feeder is used for quantitative feeding of bulk materials. The feeding process is continuous feeding with spiral rotation. The feeder conveys the materials the user's feeding bin other feeding equipment passes through the weighing bridge. Carry out weight detection; the speed sensor installed at the end also detects the speed of the spiral body; the detected weight signal speed signal are sent to the Huaqi XR series weighing controller for calculus processing, the display is in tons per hour. The instantaneous flow rate the cumulative amount in tons.

Performance characteristics

The feed screw has a unique steady flow structure, the material sinks evenly across the entire feed inlet section, which is easy to form an arch is easy to punch.

Double spiral structure, stable material flow, real weight signal, higher measurement accuracy. (Optional)

The spiral blade is made of manganese steel, which has strong wear resistance long service life.

The spiral gap is small, which overcomes the problem of backwashing avoids the adhesion of materials in the gap of the pipe wall.

Sealed structure to reduce dust flying.

The inlet outlet are soft connected, the installation angle can be adjusted arbitrarily according to site requirements

Automatic measurement calibration coefficient, automatic measurement system zero;

Put various parameters manually, the operation can be manually/automatically switched;

It has the functions of instrument self-diagnosis computer networking.

Technical Parameters

Dynamic cumulative error: ≤0.5%;

Control accuracy: better than 1%;

Instrument power supply: single-phase 220V±30%, 50HZ;

Drag power: three-phase 380V±10%, 50HZ;

Use environment: temperature: -10℃~+40℃

Humidity: 5%~90%

Weighing display controller

Huaqi XR series weighing controller is the latest instrument developed designed based on the practical experience of thousands of electronic belt scales in the past. Its main features are: intelligent, man-machine dialogue type, various information displayed in Chinese, all The operation can be completed under the prompt of the instrument, the operation calibration are particularly convenient.

In addition to automatic zero calibration, automatic zero tracking, automatic interval calibration, fault self-diagnosis, high low limit alarm, printing, communication other functions, Huaqi XR series instruments also add linear compensation, programmable analog output, programmable digital input/ Output, multi-level password protection, multiple input/output, multiple communication protocols (optional) other functions. A/D converter 16-bit, instrument accuracy 0.01%.

Performance characteristics

Circuit design: Microcomputer-based circuit design, CPU uses 8-bit, 16-bit A/D conversion

Data storage: CMOSRAM, battery can save data for up to 10 years.

Relative humidity: 95% non-condensing

Display: Chinese, LCD

Power source: wide voltage switching power supply design, 110~285VAC (50/60Hz) stable operation, strong anti-interference ability, (switch optional)

Accuracy: The error between -40 degrees +50 degrees is within 0.044% of the load cell range

The error between -10 degrees +50 degrees is within 0.022% of the load cell range

Linearity: Net weight 0% to 105% of full load, the error is less than 0.01%

Input: Weight: Millivolt signal the load cell

Speed: pulse signal the speed sensor

Output: Provide excitation voltage for load cell

For speed sensor (provide 24VDC)

Remote pulse output (proportional to cumulative amount)

Analog output: 0-20mA 4-20mA current output proportional to flow (optional)

Communication interface: RS-232/485 (optional)

Independent closed-loop control, PID self-tuning (optional)

Load cell

The load cells used in Huaqi LXC series screw scales are strain gauge tension sensors. Main Specifications:

Shell: "S" type sealed package protection

Excitation: 10~15VDC;

Sensitivity: 3.0 mv/v ± 1℅;

Creep: 0.03%FS;

Zero balance: 1% FS;

Zero temperature drift: 0.02%FS/10℃;

Input impedance: 385±3Ω;

Output impedance: 350±3Ω;

Temperature range: -30℃~+70℃;

Safe overload: 150% FS;